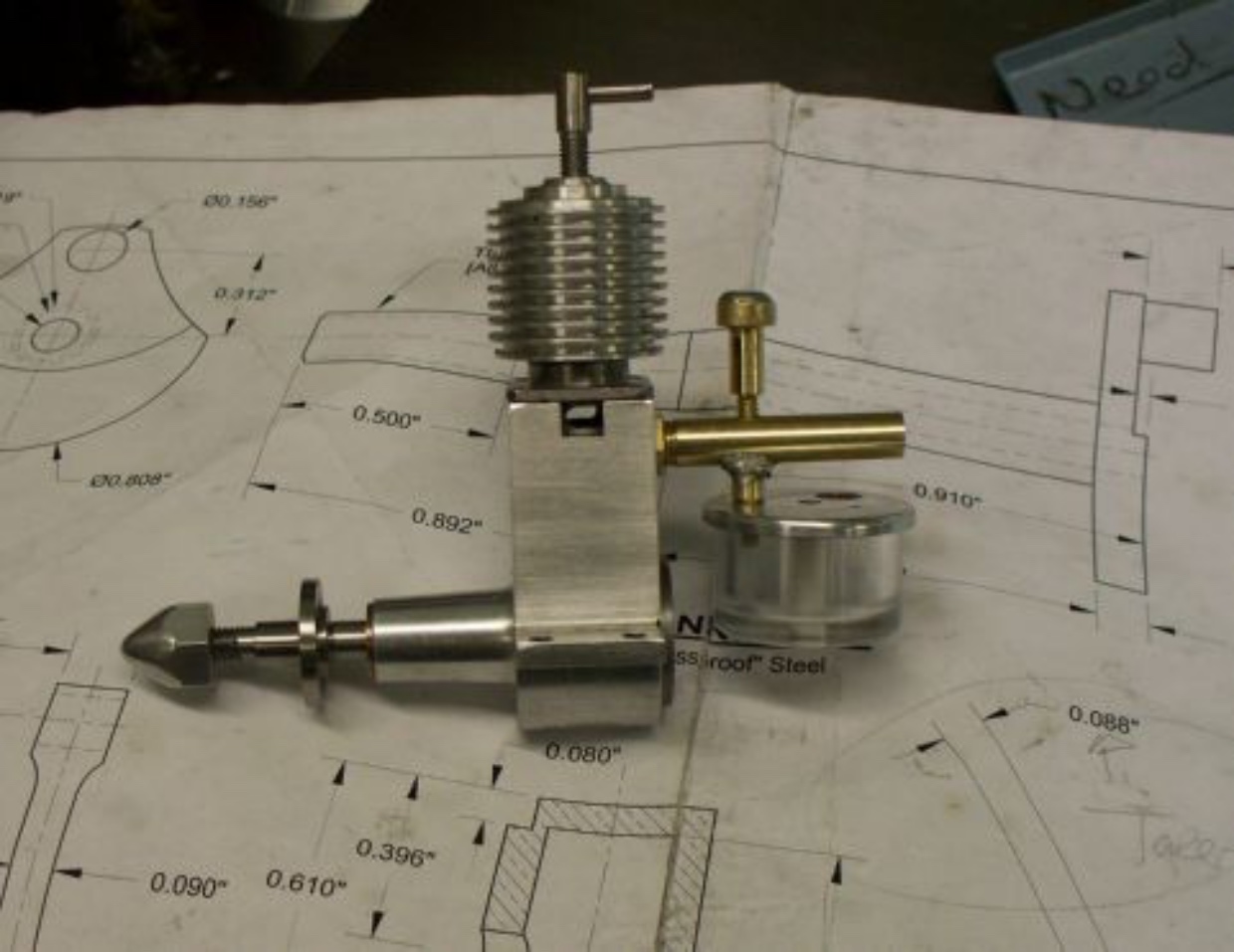

Inline boring tool made to bore Seal 15cc model engines.

Inline boring tool made to bore Seal 15cc model engines. The need to design and build my own tool came about because of the high costs of commercial systems. Since it may only ever be used once then it was a non starter..

I wanted to get the easiest and most accurate system I could. That meant having a micrometer head if I could. When going through the substantial MSC Industrial direct catalogue I spotted the very thing I wanted. I micrometer head of the right size. The completed tool is fitted into a home built box with cutouts for the parts to rest in.

There are two main parts to the boring system. First the clamp head, which holds the micrometer and secondly, the cutting bar, which holds the tool bit. In the box there are two more tool steel bits and a spare brass nut. The box itself is simply made with a self adhesive felt applied.

Sources for micrometer heads on eBay through my affiliate link:-

[ebayfeedsforwordpress feed=”http://rest.ebay.com/epn/v1/find/item.rss?keyword=micrometer+head&categoryId1=12576&sortOrder=BestMatch&programid=15&campaignid=5337996670&toolid=10039&customid=inline+boring&listingType1=All&lgeo=1&feedType=rss” items=”2″]

Pictures below show the main parts if the inline boring tool.

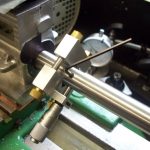

The inline boring bar in use

The operation of the tool itself is fairly straightforward. The cylinder block for the Seal engine is placed in position on the top slide and bolted down. Once that has been accurately done the bar is placed between centres and driven, in this case by the faceplate.

After the cut has been made the tool is advanced by means of clamping on the micrometer head. The grub-screw is then loosened and the micrometer advanced accordingly. Once the grub-screw is reset the next cut can taken. Checking the diameter again, the sequence is stopped or repeated according to the requirements for the casting.

For more information on any of my articles please feel free to email me or leave a comment. Many thanks for visiting.